Vacuum Infusion

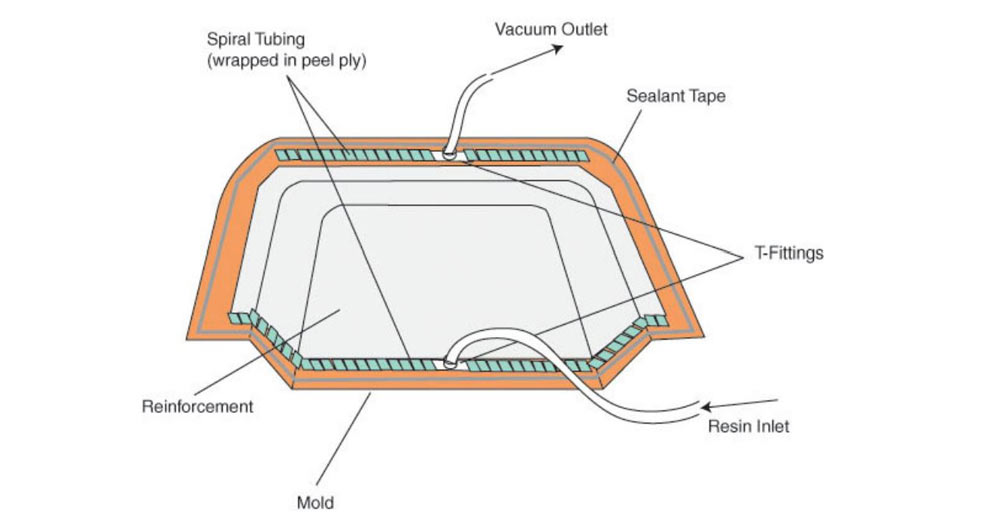

The Vacuum Infusion Process (VIP) is a method to drive resin matrix into fiber laminate by using vacuum pressure. Dry materials are laid into the mold and the resin matrix is introduced by suction or vacuum creation under a sealed bag.

Vacuum pressure will not allow excess resin matrix that maintain a very good fiber resin ratio in the final product. If in case any excess resin that is introduced will eventually be sucked out into the catch pot. As a result, only the minimum amount of resin is absorbed. This decreases weight, increases strength, and maximizes the properties of fiber and resin.

Parts constructed using this process can approach prepreg levels of resin content. Final product still depends on many variables like reinforcement material, resin, time factors, as well as others.

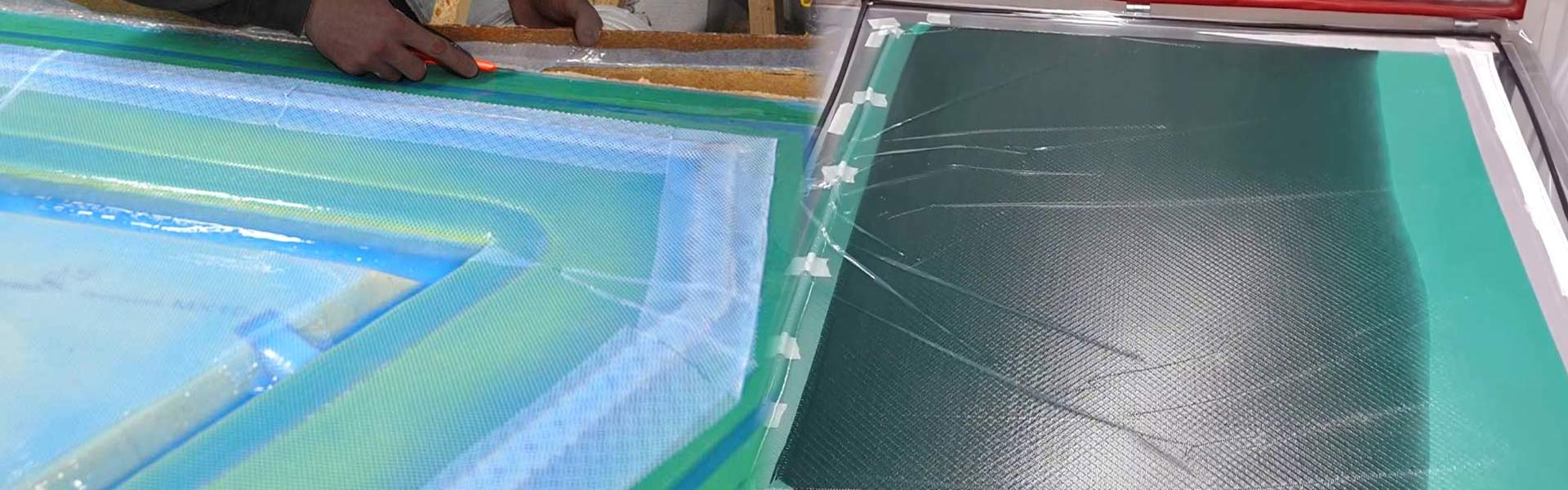

At NitPro Composites, we make multiple custom shape parts in carbon fiber composite using this method.