Pultrusion

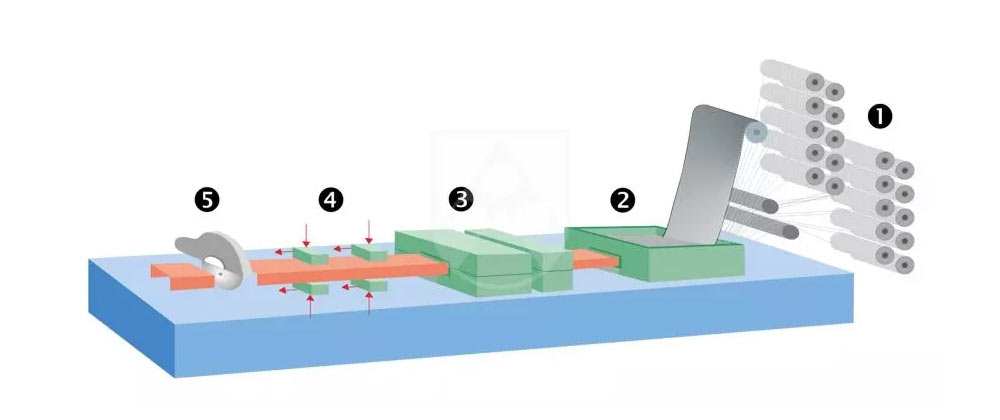

Pultrusion is an automated composite synthesis process in which continuous lengths of reinforced polymers with a constant cross-section are produced. During this process, carbon fibers, liquid matrix, and additives are normally pulled through a heated die, converting them into composite products. This process produces high strength to weight ratio part by having high fiber volume fraction.

At NitPro Composites we have a fully automatic digitally controlled Pultrusion machine to produce constant cross-section composite profiles. We have a production capacity of 30000m/month to cater to the global market. For custom profiles, we have the capacity to develop pultrusion molds to produce any constant cross-section composite profile.