Vacuum bagging

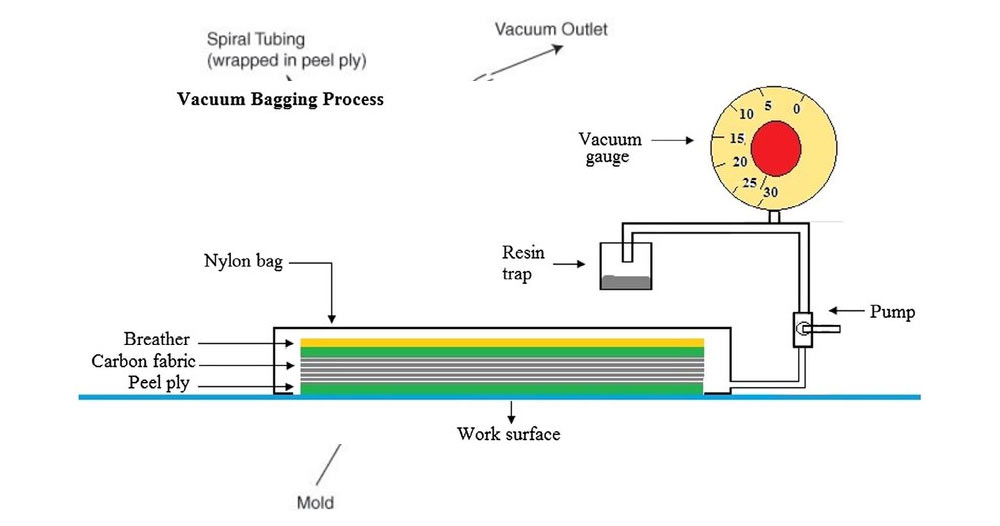

In a typical hand lay-up process resin content is very high due to manual resin application, vacuum bagging is a technique that reduce resin content. In this process reinforcements are laid into a mold and manually wet out using brushes, rollers, or through other means, now vacuum is applied to bag to suck excess resin out of the laminate. Vacuum bagging greatly improves the fiber-to-resin ratio, and results in a stronger and lighter product.

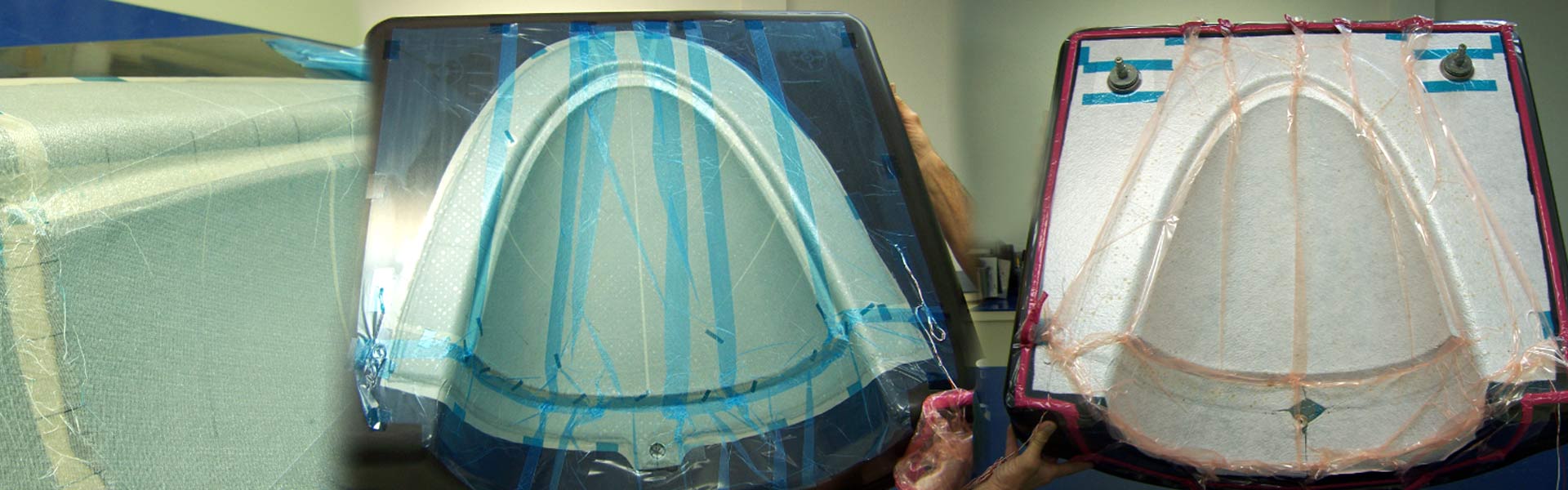

We at NitPro Composites have facility of Vacuum Bagging with all equipment for Room-Temperature as well as high temperature Applications. We have developed many products as well as prototype with this method.